Acid-resistant coating agent(EGAPOX-316)

- EGAPOX-316

- Category: For Building – Concrete Floor

- Summary: Non-toxic solvent epoxy (both upper and lower)

- Purpose: Applicable on oil, moisture, rust and FRP

- Color: Bright green, gray, reddish brown, blue, green.

- EGAPOX-316 General Characteristics

-

This shows strong adhesion for nonferrous metals (aluminum, copper, stainless steel, stick, lead, nickel, chromium, titan) and especially for FRP [SMC, BMC, and hand layer], which are extremely adhesive to the material, thus showing high adhesion to glass, tile and stone with durability and heat impact.

-

It is water-resistant because it's applied with plastic alloy to form an unusual hydrophobic structure between molecules.

-

t is hard but elastic and plastic, good for shock resistance, and is also linked to thermal properties, becoming highly heat-resistant.

-

This means that hardened paint is not permeated or eroded by water, nor is it toxic as the ingredients in the paint are not released into the water.

(For drinking water tank: 316W, For hydrothermal tank: 316HW )

-

This water resistance is not only at room temperature, but also at heated water. (Hydrothermal tank: 316HW)

-

Penetration is good enough to fit well into the rust of the steel plate.

-

Hardened coatings contain not only moisture, but also oxygen permeability, which prevents the mechanism of the concrete, thus having excellent anti-rust property to directly apply coating on the rust.

-

The friction on the surface is low and smooth, not staining easily.

-

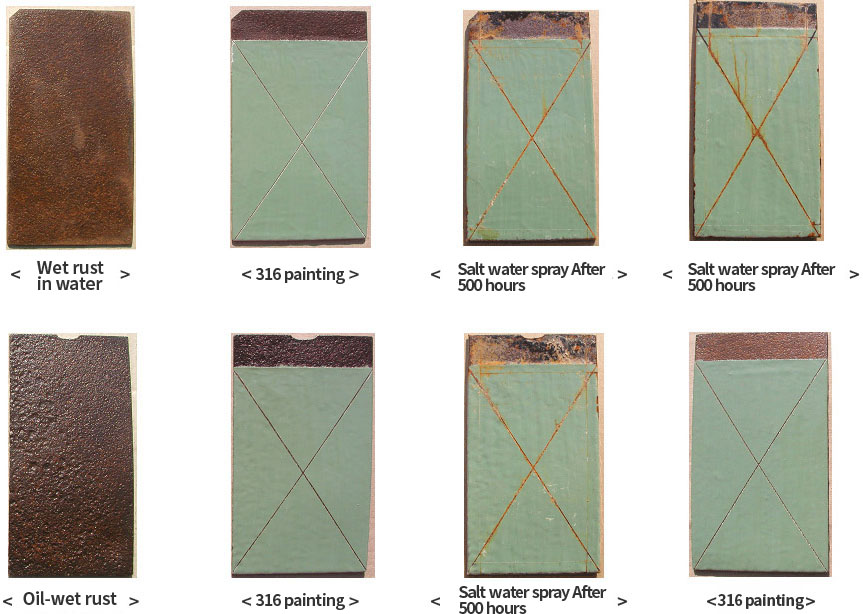

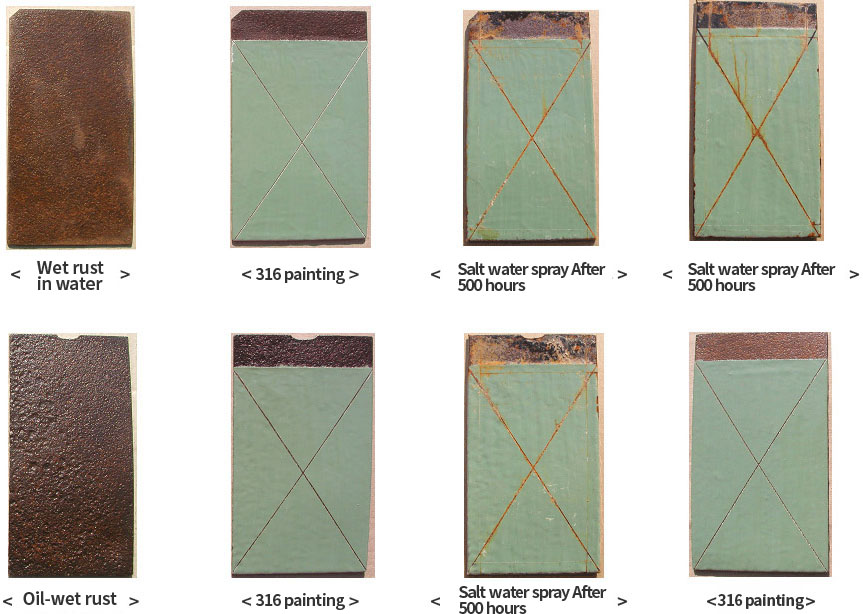

This has good wetting for even in humid surfaces, so it has good workability, showing equivalent properties and can be painted directly on moisture-soaked rust or concrete.

-

It also has an affinity with mineral oil, so its wetting is excellent even on oily surfaces, showing the same properties as in normal heating, so it can be painted directly on oil-stained rust or concrete surfaces.

-

It has excellent chemical resistance.

-

It has good electrical properties.

-

Hardening is possible even at low temperatures.

-

It has good adhesion with general epoxy material and acrylic urethane coating on top of 316.

-

Water-soaked rust, G-136 paint, after 500 hours of salt spray, oil-soaked rust, 316 paint, after 500 hours of salt spray, 316 paint

- EGAPOX-316 Applied Characteristics by Tank Material

-

Concrete Tank

-

- For concrete tanks, both newly constructed and old tanks contain a lot of water, which create many difficult problems in the public law. Because Due oil paint does not show painting ability to the moisture concrete surface, the water type is mainly used, but for evaporation of moisture in the paint film, the moisture in the tank must be continuously entilated to reduce humidity in the tank, and the coating thickness of the oil paint painted several times.

Therefore, it takes a lot of time and process to get to fresh water, and there were many mishaps that caused drinking water to be contaminated due to the lack of construction time in failure of meeting these conditions.

However, the EGAPOX-316 has good painting ability even on wet concrete surfaces, so it shows good adhesion even after curing, so it can still be worked without special drying or primer.

In addition, water-based epoxy primer can be performed if the cross section itself is not very good, but the proper response should be made when the water is contained or permeated.

The thickness of the paint film can also be adjusted arbitrarily, raising it from 100㎛ to 200㎛ every 1-2 times.

-

FRP Tank

-

- FRP tanks can be exposed to cracks or internal glass fibers due to aging and external shocks for a long period of time, and can cause small amounts of S.M in the resin, in some cases. Internal and external coating was required to solve this problem, but as most unsaturated polyester wax types, adhesion was very difficult.

EGAPOX-316 exhibits excellent adhesion over these wax-type unsaturated polyesters, making lining material of the FRP tank ideal for drinking. This displays the same effects on SMC or on hand layup-types.

However, the tank of FRP material which is used as a water tank, has a large amount of water moss on it, causing a decrease in adhesion, thus sandpaper can be applied to improve surface luminance for new and repair painting of FRP material to expect better adhesion.

-

Steel Tank

-

- Generally, new tanks or tanks in repair share many of the same challenges in an actual paint site.

The tank that has just been manufactured is either covered with rustproof oil or treated for the purpose of rust prevention, which prevents the adhesion of the paint, and the welding part is tarnished or does not have complete paint conditions.

Also, for the repair tank, it is difficult to remove the tarnish part completely, it is difficult to glue the paint due to moisture or fine condensation on the surface, and there is a high risk of tarnishing again.

In such a case, EGAPOX-316 is suitable for use in steel drinking water tanks as it has excellent paint and adhesion and water resistance on rust, including molten iron plates, and even moisture.

However, when painting on a rusty surface, make sure to remove any rust that falls or scales.

-

Stainless Steel Tank

-

- In recent years, many grade stainless steel with good corrosion resistance have begun to be used as tank material.

Above the odd part, however, corrosion occurs due to chlorine contained in the tap water, and the iron is extracted from the welded part, resulting in rust.

Epoxy varnish is applied to prevent this, but it is extremely difficult to satisfy adhesion, water resistance, strength and workability of stainless steel at the same time.

Moreover, in the tank manufacturing process, oil has not been completely removed, causing the adhesion to be reduced, but EGAAPOX-316 can meet all requirements with simple de-greasing.

-

Reservoir, waterway, and sewer lining

-

- This is used in reservoir tanks or pipes for general water or sewage, as well as for drinking water. EGAPOX-316 especially shows the true worth in workability and performance in situations where moisture is high or cannot be completely removed during repair.

Its durability is also high, so it is more economical than conventional products that use general pre-processing methods.