Glass Insulation Coating Agent

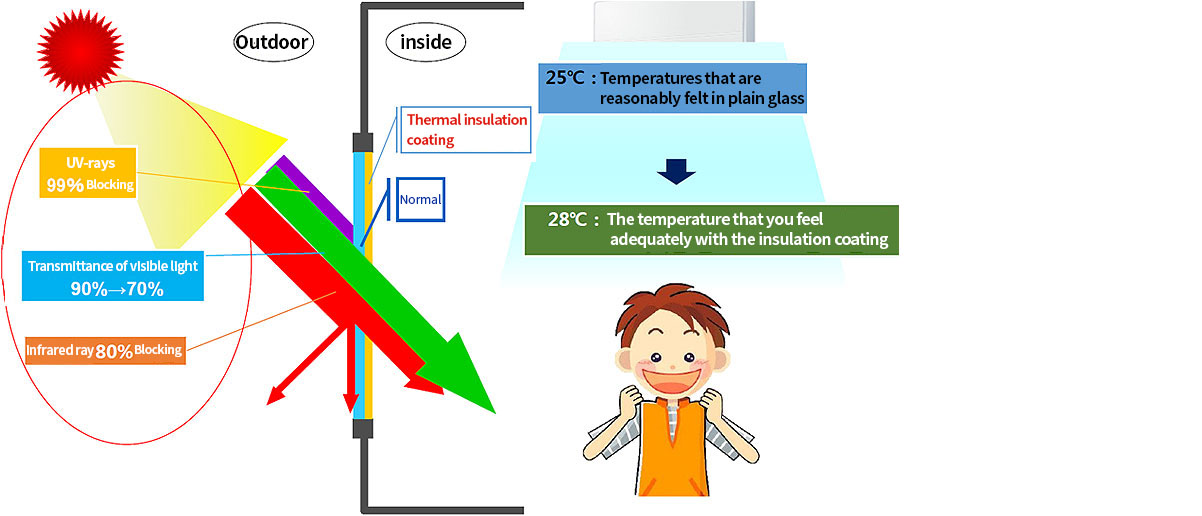

Heat Insulation Glass Coating [Infrared-Ultraviolet Blocking Coating]

-

- What is Energy-saving glass coating agent?

- Effect of 14%annual energy savings (heat and insulation)

-

-Blocking 5~10℃ of direct heat in summer, reducing approx. 3℃ of indoor temperature

-

-Increasing 1~3℃ of indoor temperature in winter, with max. 21% of power saving

-

-The larger the area of the glass, the greater the effect.

- 50%Condensation Inhibit

-

- Excellent durability (10-year warranty)

- UV protection (99%) prevents skin damage and deterioration of household products

- Prevention of liceworm (moths, lotus flowers in summer)

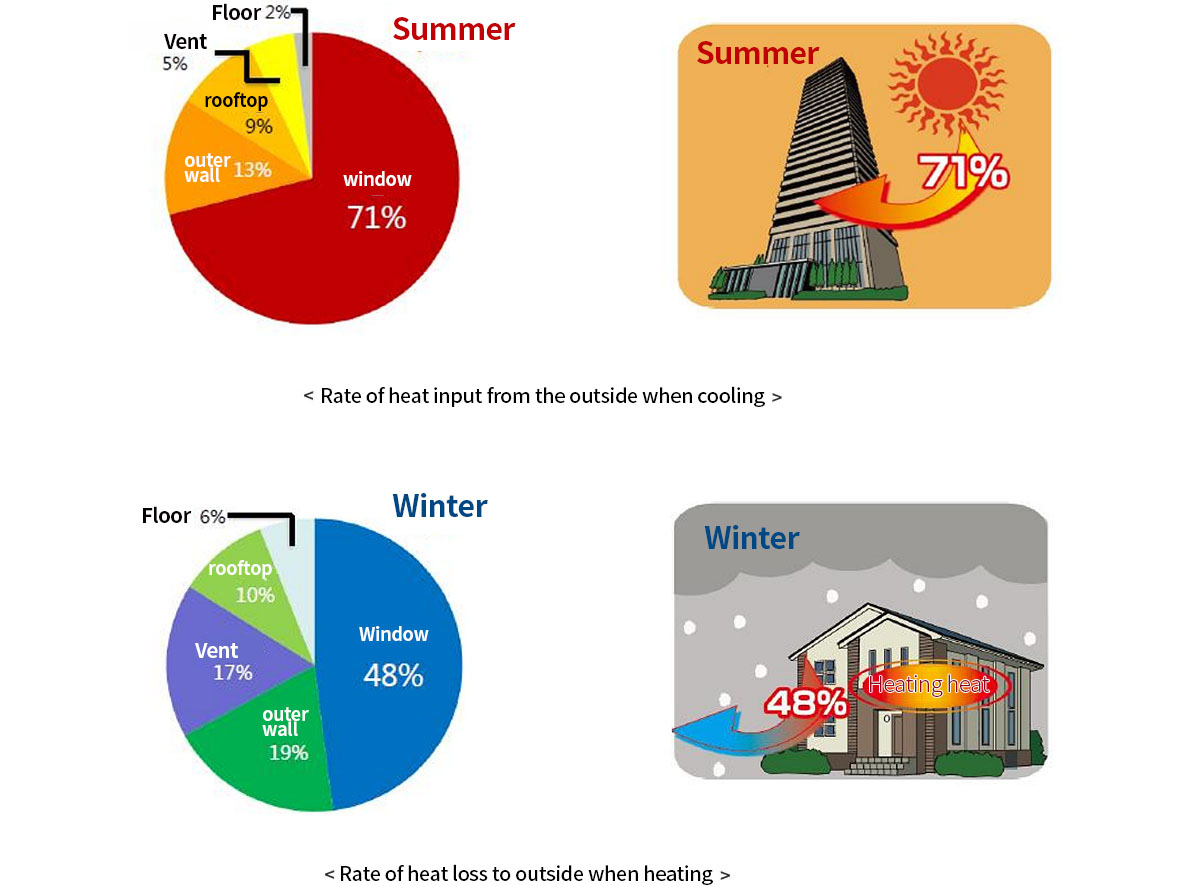

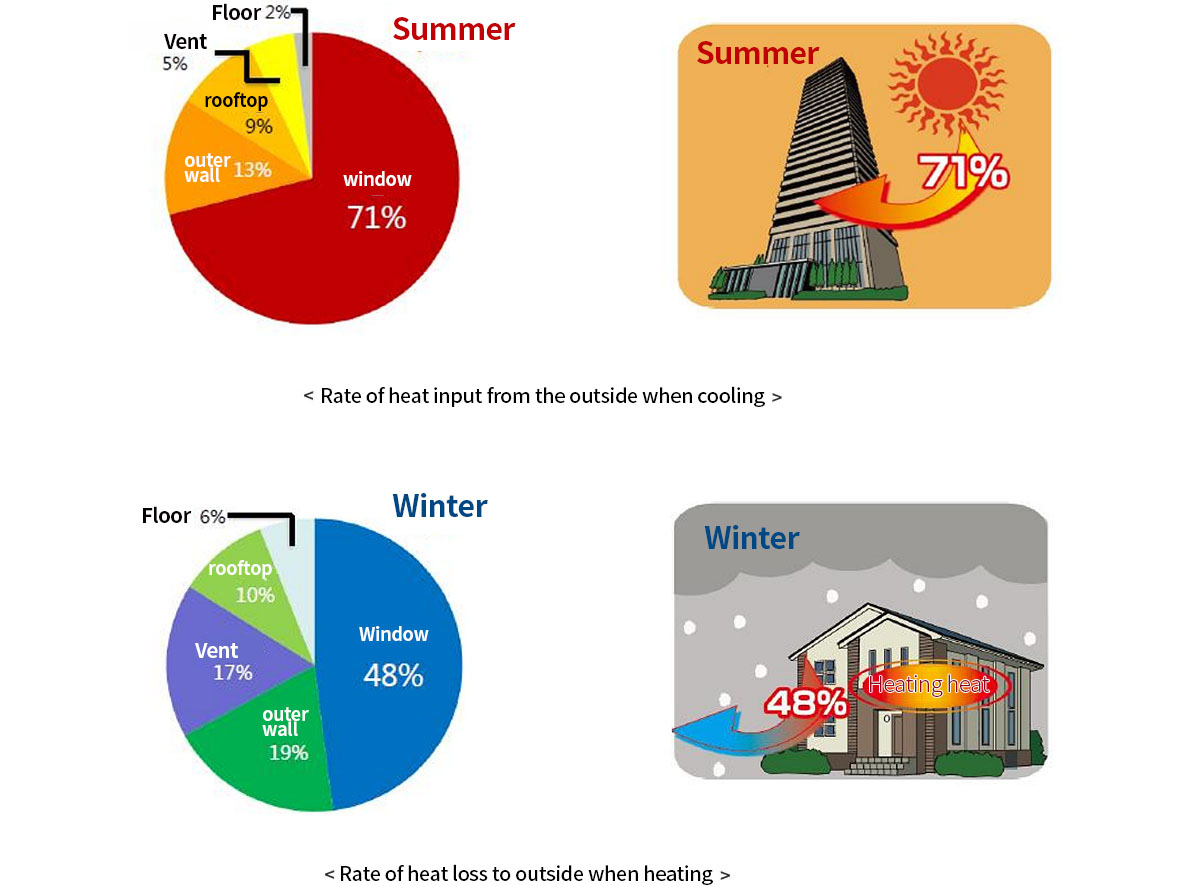

- Heat access ratio in buildings

-

Heat access of buildings results in 71% of heat coming in through the windows during summer and 48% of heat lost during winter.

Measures to supplement existing windows is the most important.

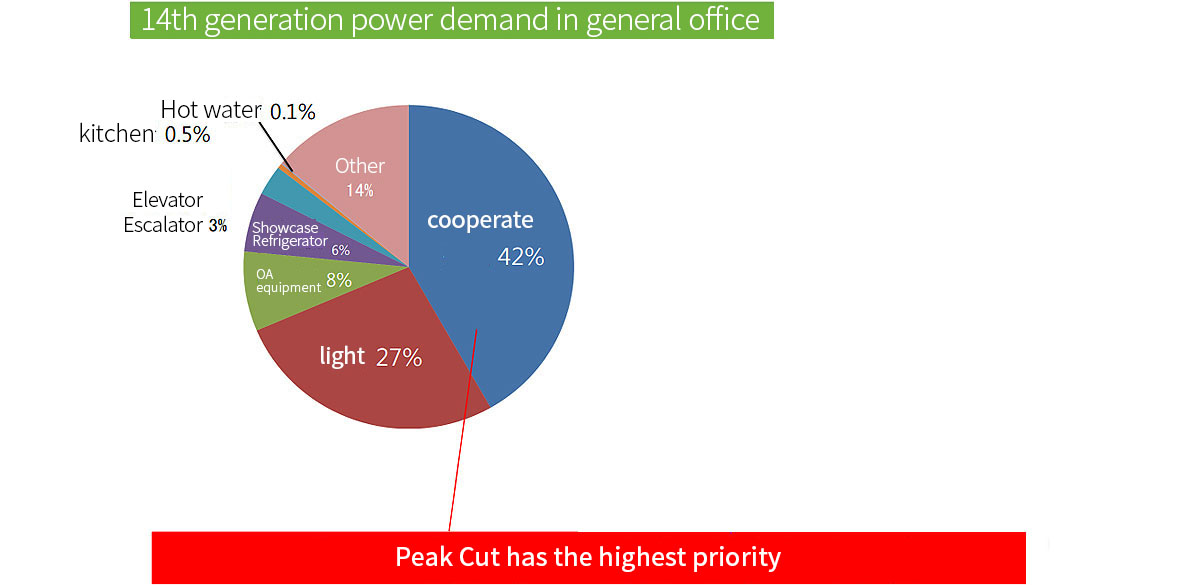

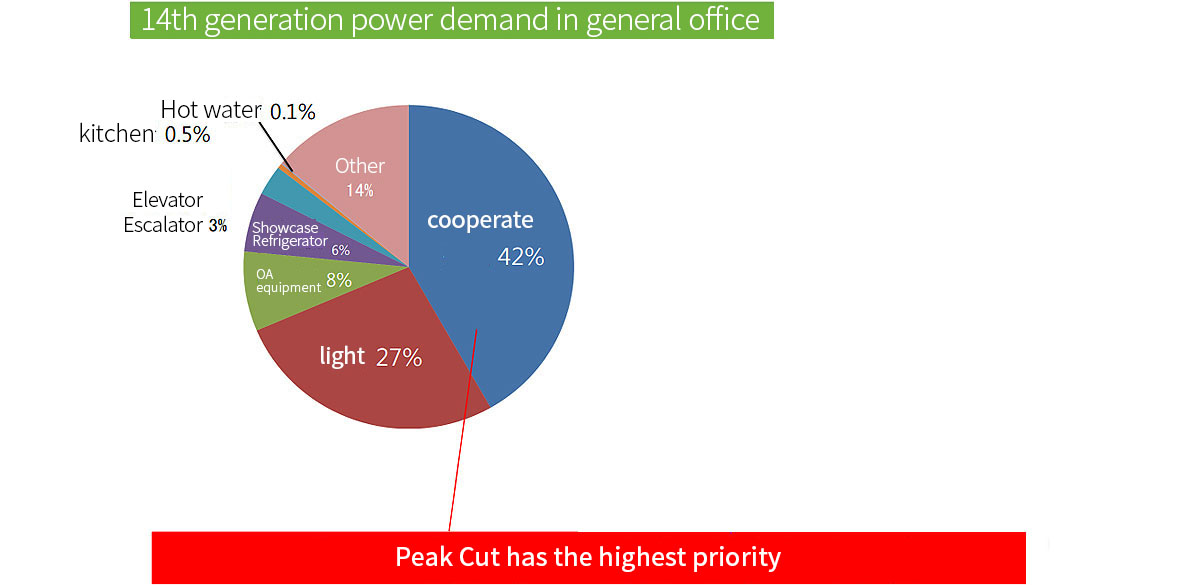

- Basic Study on the Power Countermeasures in Summer

- Basic Study on the Power Countermeasures in Summer

-

Comparison data on CO₂ reduction when implementing each power saving measure at a cost of 100 million won

-

| Initiatives |

ost (million won) |

CO₂ reduction effect [t-co₂] |

CO₂ reduction effect per 100 million [t-co₂ million won] |

| High-insulating material |

5920 |

-22771 |

-3.85 |

| High-reflective applicator |

3222 |

7007 |

2.17 |

| Glass heat transfer film |

2477 |

117270 |

47.35 |

| Roof Greening |

7900 |

3756 |

0.48 |

| Ground Heat Pump |

10764 |

46208 |

4.29 |

| Ground Greening |

6100 |

10124 |

1.66 |

| Porous Pavement |

5424 |

7791 |

1.44 |

※ It has been proven that the window heating measures have the highest cost-savings effect

< Cost and CO₂ Reduction Effect Relationship >

- Product Characteristics

-

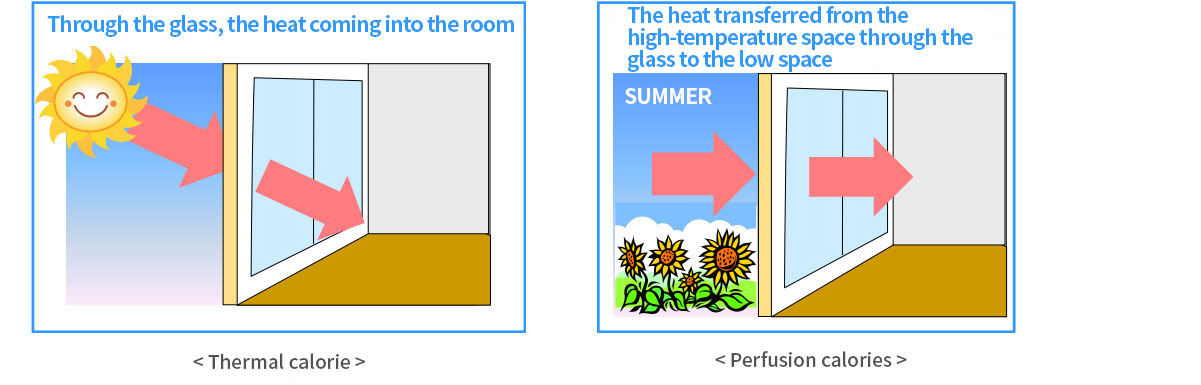

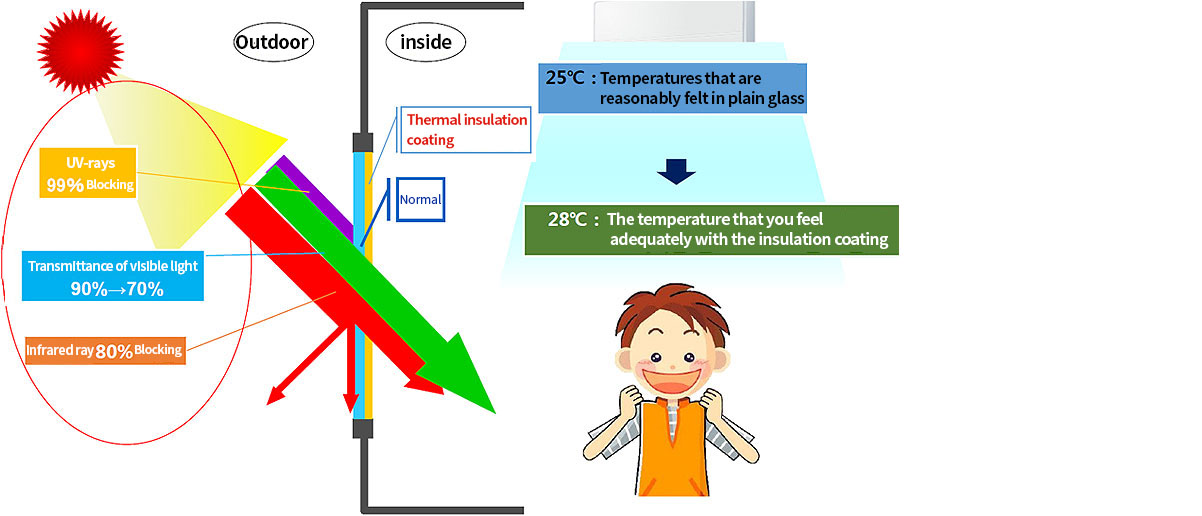

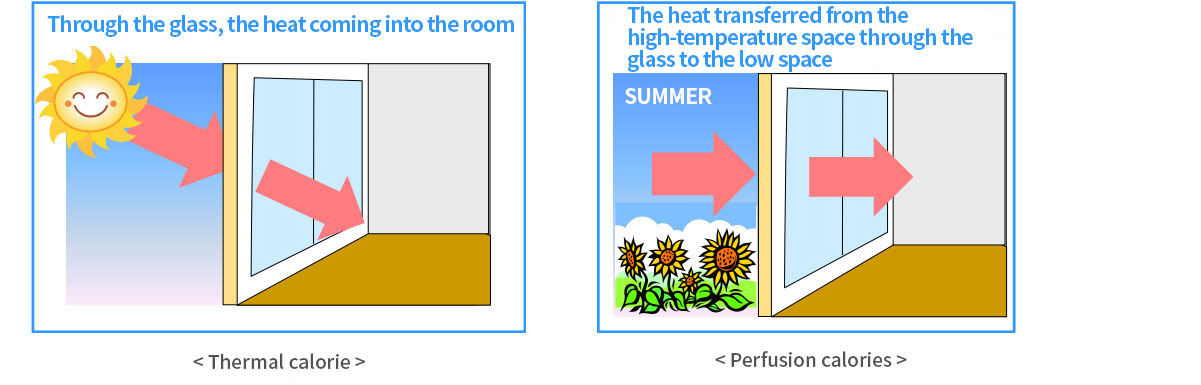

Summer: Blocking 5~10℃ of direct heat, Lowering 2~3℃ of indoor temperature, power saving effect of 14~21% per year to reduce air conditioning load (Based on KEMCO: 7% power saving effect if 1℃ is lowered in summer) Preventing heat from sunlight and transmission.

- Product Characteristics 1: Heat transfer effect (Principles of Summer Heat Effect))

-

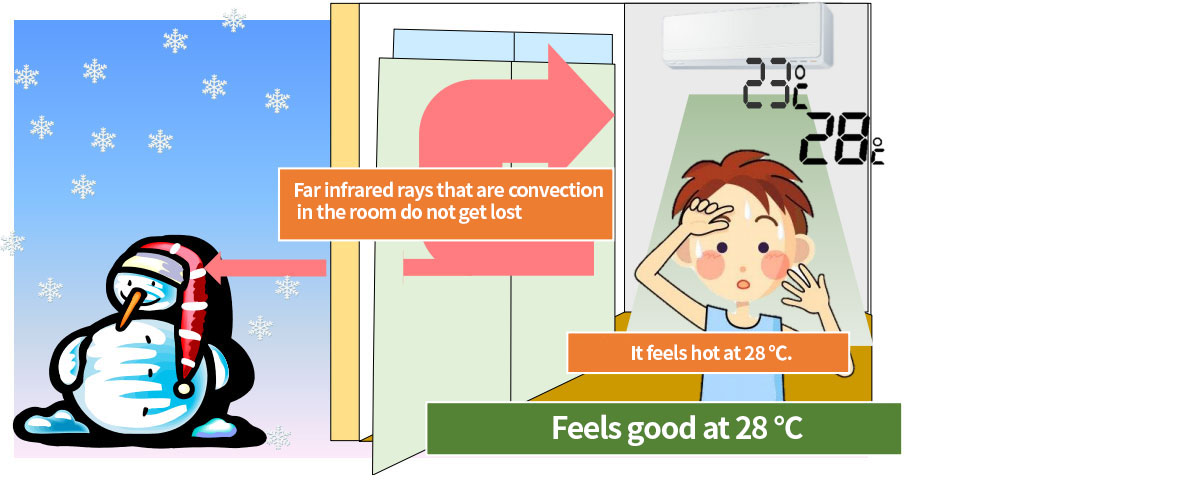

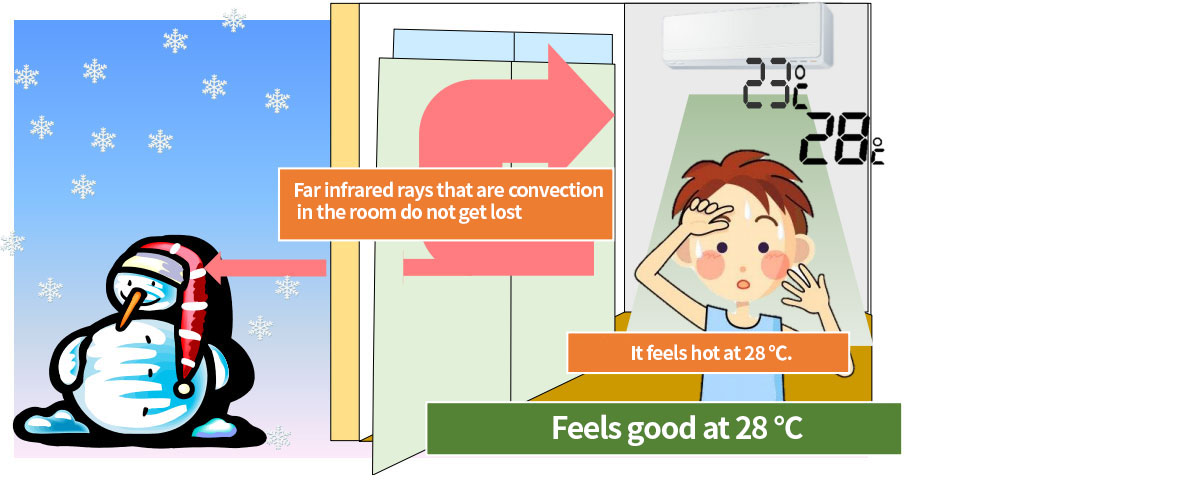

Winter: Heat retention effect by preventing release of far-infrared rays from indoor. Increasing 1~3℃ of indoor temperature. Max. 21% of power savings effect

- Product Characteristics 2: Insulating Effect

-

Winter: Heat retention effect by preventing release of far-infrared rays from indoor. Increasing 1~3℃ of indoor temperature. Max. 21% of power savings effect

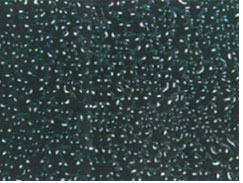

- Product Characteristic 3: Condensation suppression effect (Screen zoom)

-

| Category |

General glass |

Glass with liquid coating |

| Condensation image |

|

|

| Generating time |

30mins |

60mins |

※ It is difficult for water to flow down, inhibiting condensation more than 50%.

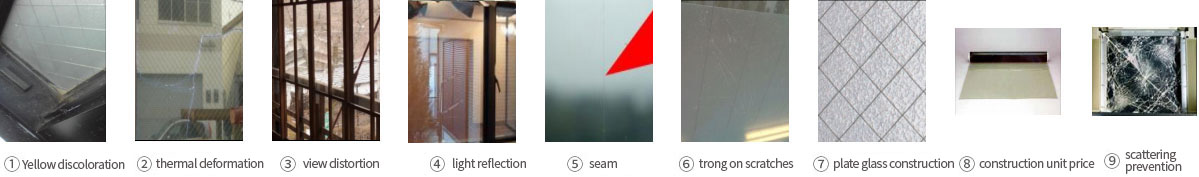

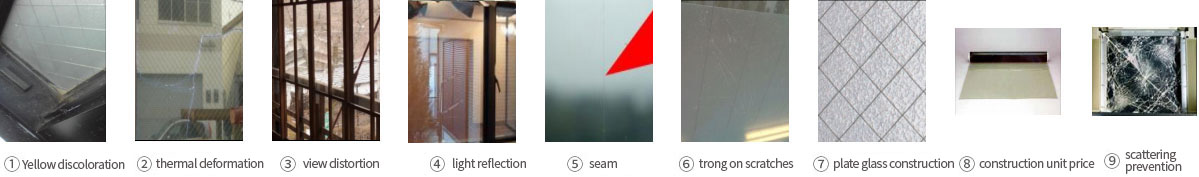

- Comparison with curren film 1

-

| Current film |

liquid coating agent |

- Discoloration: Stripping

-

Durability of the fabric is shorter to 5~7 years due to deterioration of the fabric

Corner peels easily due to deterioration by silicon oil. Yellowing present.

|

- Discoloration: Stripping

-

Maintaining about twice as much durability as film. Yellowing present.

10~15 years of durability. 10-year warranty!

|

- Thermal deformation

-

Susceptible to thermal deformation

|

- Discoloration: Stripping

-

Heat distortion rarely occurs because it is the same expansion factor as above.

|

- Distortion of view

-

Surface and jointing and visual distortion are likely to occur.

|

- Discoloration: Stripping

-

There is little or no distortion of view.

|

- Reflection of light

-

It's hard to see outside because of the reflection of indoor light at night. Also, the acceleration of urban heat island phenomenon.

|

- Reflection of light

-

There is no reflection of light even at night.

With little daylight sun reflection, it has little effect on the urban heat island phenomenon (tropical).

|

- Seam

-

Seams are formed when large glassware is constructed.

|

- Seam

-

It has no seams because it is coated with a roller.

|

- 단열 유리 코팅

-

“기존 건물에도 간단하게 시공 가능! 초대형 시장의 문은 이제 막 열렸을 뿐입니다.”